Through its fully fluoridated high-temperature stability, chemical inertness and oxygen compatibility, Krytox™ 227 reduces your maintenance costs while improving performance and reliability. Krytox™ 227 is the ideal solution for lubricating convection reflow ovens as it performs as intended at temperatures as high as 288 ☌. In addition to excellent lubrication, it provides protection against oxidation, humidity, wear and corrosion. Other devices depend on IR preheating or air temperatures above the vapor layer to heat the element in preparation for soldering. It’s able to provide long-lasting lubrication, increasing the reliability and durability of the machinery while reducing re-lubrication intervals. Krytox™ 227 is a high-performance grease that can be used to lubricate the shaft of the conveyor mechanism within convection reflow ovens. Krytox™ 227 for the Maintenance of Convection Reflow Ovens The Mistral 260 convection reflow soldering ovens use re-circulated hot air to accomplish reflow at much lower temperatures than IR systems.

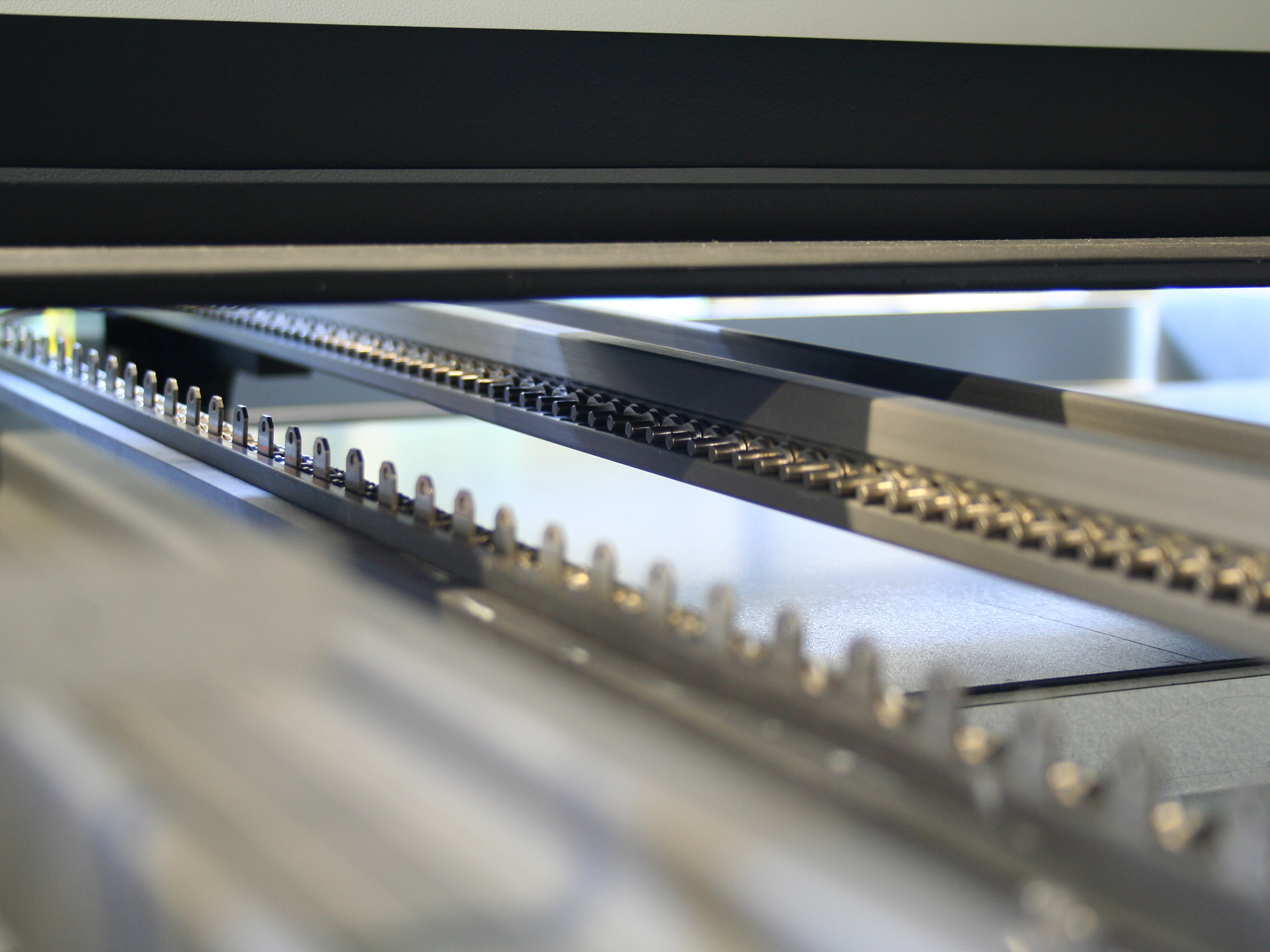

Increase safety and reliability of machinery.Lower total repair and maintenance costs We introduce The Lizard Demands for a modern oven are not only in soldering and curing, but in particular in zone regulation.Through using quality lubricants, you will be able to: Lubrication is one of the most important parts of the maintenance process. Conveyor mechanism being cleaned and lubricated The reflow soldering of through-hole components using solder paste in a convection oven process is called intrusive soldering.Main chamber being vacuumed and cleared of soldering residue.Automatic oiler level being checked and maintained.Routine maintenance of convection reflow ovens consists of a thorough inspection of all parts, including:

Advantages of Convection Reflow OvensĬonvection reflow ovens are advantageous to manufacturers by providing:Īs convection reflow ovens can be used for the mass-soldering of PCBs, especially in facilities where many are manufactured each day, it’s important that they are maintained sufficiently in order to prevent unexpected downtime as much as possible. This growth is accounted for by increasingly innovative convection reflow ovens which are pushing manufacturers to optimise their reflow soldering processes further than before. The global reflow ovens market is estimated to reach a value of £286 million by 2027, growing at a CAGR of 4.1%. The PCB is placed on a conveyor belt that moves through the oven, being subject to different amounts of heat and cooling at each stage. ▽ Customized reflow soldering oven for HUAWEI (5G products) Shenzhen, Qingdao, Dongguan, Wuhan factory.Convection reflow ovens are machines that enable efficient reflow soldering of electronic components onto printed circuit boards (PCBs).Ĭonvection reflow ovens contain various sections which can be individually temperature-controlled for the optimal reflow soldering of the components.

CONVECTION REFLOW OVENS FULL

▽ Poland customer ( Battery Chargers and Adapters) - Full SMT production line ▽ Russia customer - Full SMT production line Use imported motors, speed adjuster, smoothly running, adjustable speed at 0-2000mm/min. Independent cooling area ensures the low temperature when PCB comes out. Both top and bottom zones hot air heating,good heater compensatory,High thermal efficiency,energy saving,speedy heating,suitable for soldering components like BGA,CSP etc.Special forced hot air circulation structure makes PCB and components heat evenly, Temperature Accuracy ± 1.5 ☌, room temperature settling time less than 20 minutes.

0 kommentar(er)

0 kommentar(er)